GÖPEL electronic GmbH

Applications

PILOT AOI

Automatic Optical Inspection

Formats Tools Used

Delphi

Delphi

Challenges

AOI systems are now standard in almost every electronics manufacturing facility. Optical test methods have existed since electrical assemblies were created. They are used to check the visible quality features of an assembly. GÖPEL electronic GmbH, based in Jena, Germany, is a world leader in the development and manufacturing of electrical and optical measurement and test equipment.

Results

The PILOT AOI software from GÖPEL electronic is a perfect example of how a medium-sized company can develop high-quality software with Delphi in a cost-effective and flexible way. For 25 years GÖPEL electronic has been programming the AOI software very successfully with Delphi. The company is internationally successful for more than 600 customers and considers itself to be at the forefront of the industry in Europe.

AUTOMATIC OPTICAL INSPECTION (AOI) IN 3D

The Company

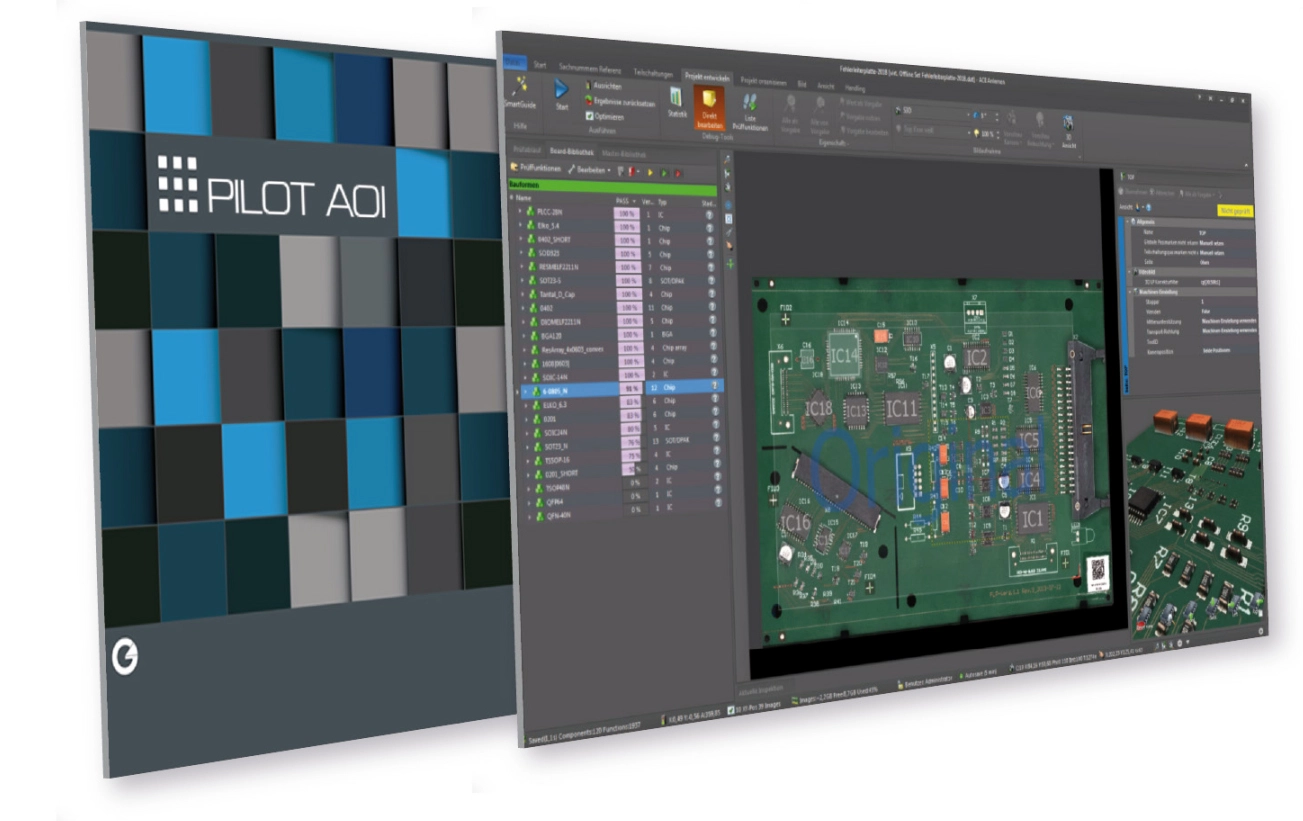

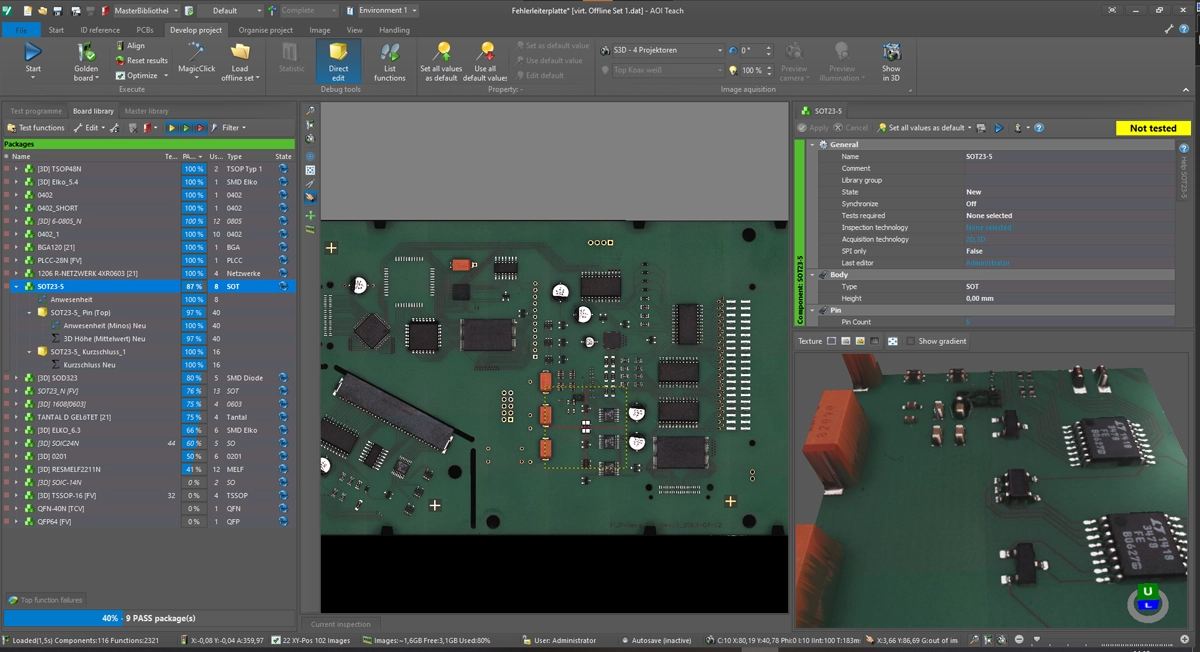

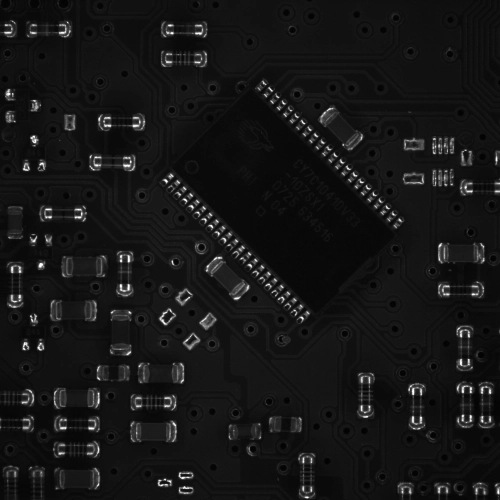

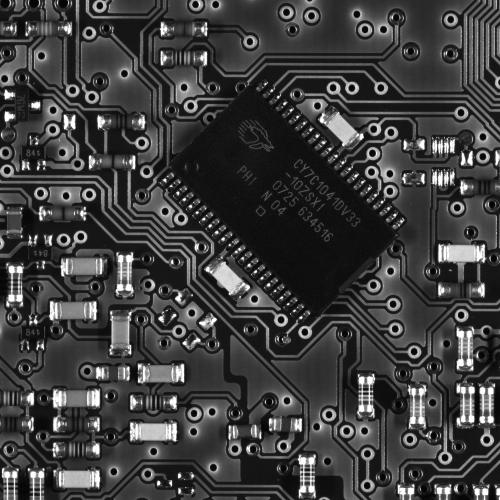

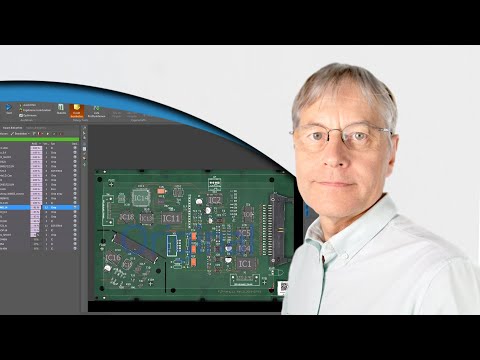

GÖPEL electronic GmbH, based in Jena, Germany, is a world leader in the development and manufacturing of electrical and optical measurement and test equipment as well as test and inspection systems for electronic components, assembled and printed circuit boards, industrial electronics, and automotive electronic systems. The devices range from stand-alone solutions for single inspections to inline systems in production lines. The optical inspections are performed with moving cameras above the respective assemblies. Test parameters include whether or not the solder paste has been correctly applied to the circuit boards beforehand, whether or not the components have been correctly fitted to the assemblies, and whether or not the solder joints have been correctly executed. The machine performs the task of quality assessment by taking digital images of the assembly to be inspected. These images are then evaluated via software algorithms using the 3D PILOT AOI software created in Delphi. All this is done at high speed with reliable and reproducible results.

Challenge

AOI systems are now standard in almost every electronics manufacturing facility. Optical test methods have existed since electrical assemblies were created and tested. They are used to check the visible quality features of an assembly. This includes the correct assembly of a printed circuit board and the inspection of solder joints. Nowadays, we have the pure 2D image in which only a color value is determined combined with 3D technology, in which additional valuable height information is obtained in addition to X and Y values. This allows physical parameters to be interpreted. A combination of 2D, 3D, and an oblique view additionally increases the reliability in the evaluation of inspection characteristics.

The Application

Similar to the ongoing development of Delphi, the PILOT AOI software from GÖPEL electronic is also adapted to the current hardware, the requirements of the customers, and the infrastructure of the company with each release. A significant factor here is Delphi’s many years of technological consistency. For a company it is essential not only to be able to use the know-how and algorithms developed over the years but also to be able to adapt to new platforms and methods in a fast and resource-saving way.

Even such fundamental changes as the switch from 16- or 32-bit to 64-bit or the changed handling of strings could be implemented in Delphi with little effort, and thus very economically for the company.

Over the years, it is a huge advantage that Delphi offers high technology consistency and efficiency.

Stephan Rabich, Project Manager Software, GÖPEL electronic GmbH

It is a basic requirement that a customer who has an inspection system in use is able to create their own inspection routines, the definitions of the PCBs and components, as well as the inspection tasks flexibly and independently with the PILOT AOI software. The visual interface allows different views of the assemblies, settings, and analyses. In addition, there is a fully automatic component library with the company’s internal part numbers and automatic adjustments of the inspection parameters based on sample assemblies.

The developers have added a special feature to the AOI software with the “MagicClick” module. This allows inspection programs to be created and optimized fully automatically with 3D AOI. Without any library entry, a production-ready inspection program including a component library is generated in just a few minutes.

The main task of the inspection software is the evaluation of the camera images and the assessment of the printed circuit boards. An essential step in development and quality improvement was the change from 2D to 3D image processing a few years ago.

In order to be able to evaluate the image data, the developers use various external image-processing libraries that are accessed via Delphi. The image data is stored and processed directly in binary format. The connection to a programmable logic controller (PLC) then leads to the necessary further steps in the production process. Currently, the application is used for each test system on Windows and consists of five main programs with a total of approximately 1 million program lines. As with every software project, there are milestones at regular intervals that lead to major changes. In some cases, these include release changes for Delphi, and at other times, essential functions are added or changed in a project. At GÖPEL electronic, for example, the latter is a permanent development and adaptation to the machine types.

I am a fan of building an application monolithically. You should be able to copy or easily distribute a finished application without having to worry about additional runtime libraries of different framework versions on the target devices. Delphi can do that.

Stephan Rabich, Project Manager Software, GÖPEL electronic GmbH

Conclusion

Software development in companies should not follow any current hype, because developments usually run permanently over many years. The PILOT AOI software from GÖPEL electronic is a perfect example of how a medium-sized company can develop high-quality software with Delphi in a cost-effective and flexible way. For 25 years GÖPEL electronic has been programming the AOI software very successfully with Delphi; they do not miss anything and are always technologically up to date. When upgrading to the new Delphi versions, the adaptation effort is mostly relatively low because the necessary adaptations were known beforehand. There are first considerations to supplement parts of the software by mobile devices, because of the multi-platform option in Delphi. You are guaranteed to stand out from the competitors with just a few small steps.

The company is internationally successful with more than 1,000 installations for more than 600 customers and considers itself to be at the forefront of the industry in Europe.

For more information about GÖPEL electronic and the AOI systems, please visit:

https://www.goepel.com/en/inspection-solutions/aoi.html

Besides Delphi, we have also started projects with C++ and C#, but no software has made it so economical and easy to develop GUI-heavy applications from scratch so quickly.

Stephan Rabich, Project Manager Software, GÖPEL electronic GmbH

In particular, we managed the release upgrades to newer Delphi versions relatively quickly. Existing algorithms and program parts could easily be taken over.

Frank Hauswald, Software Developer, GÖPEL electronic GmbH